// APPLICATION SCENARIO //

|  |  |

Landfill | Wastewater lagoon | Slag tailing ponds |

|  |  |

| Culture pond | Agricultural irrigation | Swales |

// PRODUCT PARAMETER //

| LLDPE (Execute GRI GM-17) |

|

// COMPANY PRESENTATION //

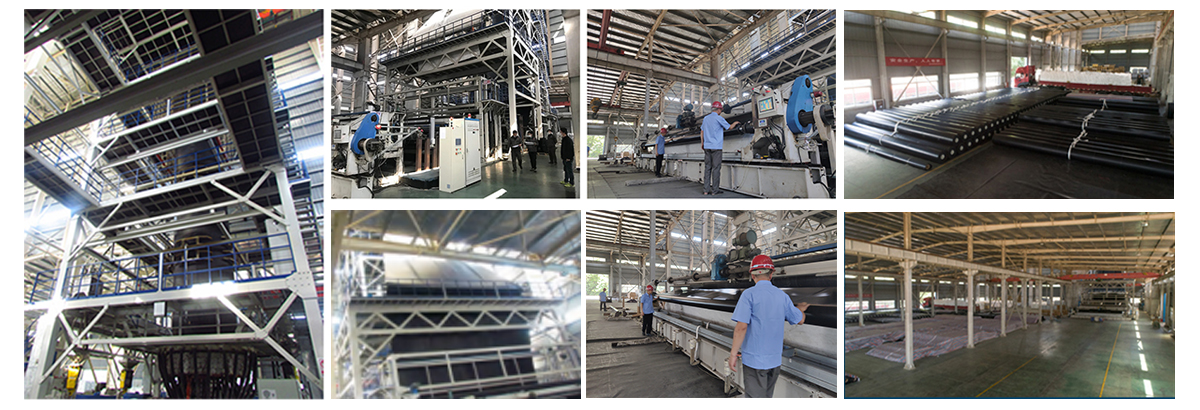

// EQUIPMENT //

// EQUIPMENT //

// LABORATORY //

// HONOR //

// HONOR //

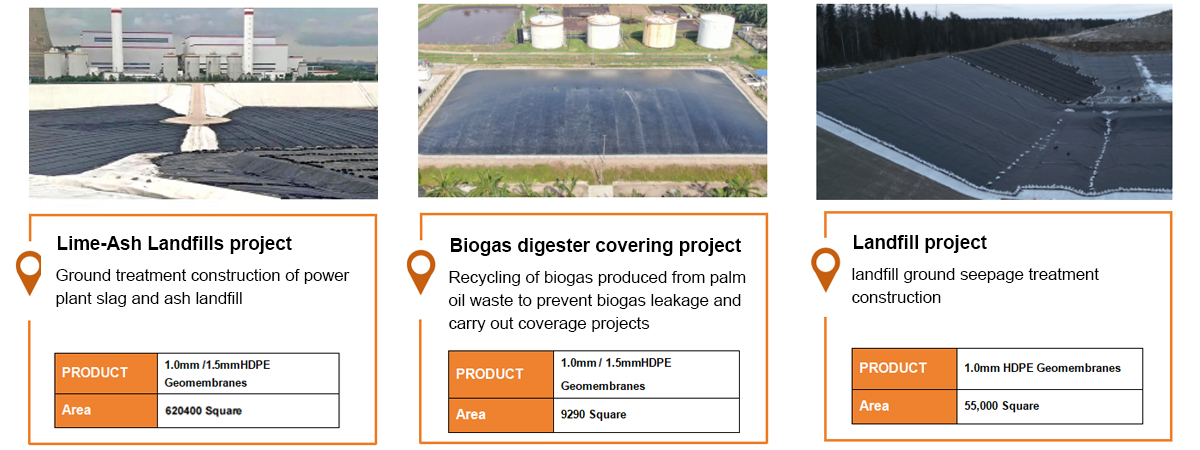

// PROJECT ENGINEERING //

Engineering case | Supply product | |

1 | Coal power project ash landfill project | 1.0mm HDPE Geomembranes |

2 | Potassium salt seepage control system engineering | 1.0mm HDPE Geomembranes |

3 | Smelter industrial waste water tank seepage prevention project | 2.0mm HDPE Geomembranes |

4 | Chemical gypsum slag field seepage prevention project | 1.5mm HDPE Geomembranes |

5 | Calcium free chromium residue wet detoxification and chromium recovery project | 2.0mm HDPE Geomembranes |

6 | Urban waste comprehensive treatment site upgrade project | 1.0mm HDPE Geomembranes |

7 | Solid waste disposal center safe landfill site | 1.5mm、2.0mm HDPE Geomembranes |

8 | Sewage diversion and biogas diversion project of domestic waste landfill | 2.0mm HDPE Geomembranes |

9 | Industrial solid waste disposal center project | 2.0mm HDPE Geomembranes |

10 | Livestock and poultry waste disposal and utilization project top membrane project | 1.0mm HDPE Geomembranes |

11 | Heavy metal waste resource harmless disposal project rigid landfill project | 2.0mm HDPE Geomembranes |

12 | Power plant dust ash landfill project | 1.0mm、1.5mm HDPE Geomembranes |

13 | Solid waste ash project in landfill reservoir area | 1.0mm、1.5mm HDPE Geomembranes |

14 | landfill storage pool covering project | 2.0mm HDPE Geomembranes |

15 | Emergency landfill project Geotechnical material laying project in the second landfill area | 1.5mm 2.5mm HDPE Geomembranes |

The project is constantly updated | ||

// MORE PRODUCTS //