1, TP-GEO Double-sided Textured geomembrane is made of polyethylene resin (PE) as raw material, adding nanoscale carbon black and other additives.

2, With excellent anti-aging, anti-ultraviolet linearity, anti-oxidation, chemical corrosion resistance and resistance to biological enzyme degradation.

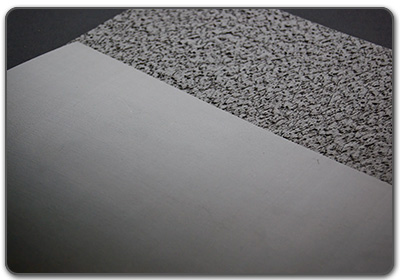

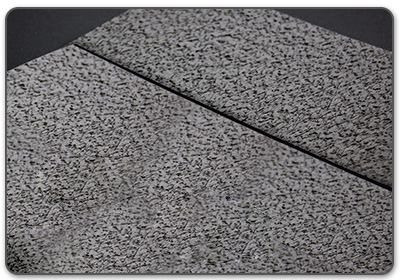

3, Double-sided Textured geomembrane surface is composed of irregular convex and convex structure, high friction coefficient, generally used in steep slopes or slopes.

4, Good tensile strength, high elongation at break.

// SORT //

|  |  |

| Smooth | Single-sided | Double-sided |

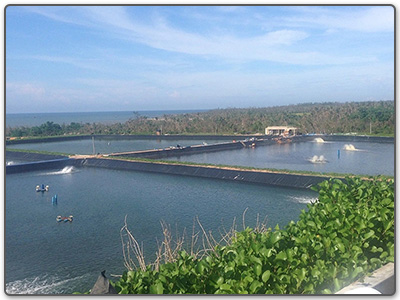

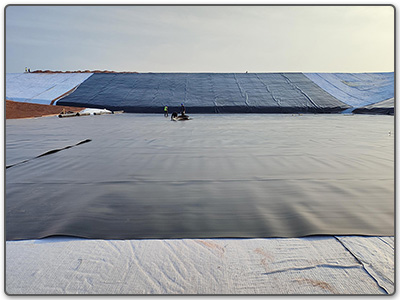

// APPLICATION SCENARIO //

|  |  |

Landfill | Anaerobic digestion ponds | Slag tailing ponds |

|  |  |

Wastewater lagoon | Swales | water reservoirs |

|  |  |

| Cultured fish pond | Mining heap leach | Slag tailing ponds |

// PRODUCT PARAMETER //

| HDPE Single-sided Textured (Execute GRI GM-13) | |||||||

Index | Unit | Test value | |||||

1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm | ||

Roughness height | mm | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

Minimum density | g/cm³ | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 |

Tensile property | |||||||

Yield strength(stress) | N/mm | 15 | 18 | 22 | 29 | 37 | 44 |

Breaking strength(stress) | N/mm | 10 | 13 | 16 | 21 | 26 | 32 |

Yield elongation | % | 12 | 12 | 12 | 12 | 12 | 12 |

Elongation at break | % | 100 | 100 | 100 | 100 | 100 | 100 |

Right Angle Tearing strength | N | 125 | 160 | 190 | 250 | 315 | 375 |

Puncture strength | N | 270 | 335 | 400 | 535 | 670 | 800 |

Resistance to environmental stress cracking | H | 300 | 300 | 300 | 300 | 300 | 300 |

Carbon black | |||||||

Carbon black content (range) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

Oxidation induction time(OIT) | |||||||

Standard OIT | min | 100 | 100 | 100 | 100 | 100 | 100 |

High pressure OIT | min | 400 | 400 | 400 | 400 | 400 | 400 |

85℃ Oven aging (minimum mean) | |||||||

After 90 days of baking, standard OIT | % | 55 | 55 | 55 | 55 | 55 | 55 |

After 90 days of baking, | % | 80 | 80 | 80 | 80 | 80 | 80 |

Uv resistance | |||||||

1600 hours of UV exposure, standard OIT | % | 50 | 50 | 50 | 50 | 50 | 50 |

1600 hours of UV exposure, | % | 50 | 50 | 50 | 50 | 50 | 50 |

Impact embrittlement performance at -70℃ | pass | ||||||

Gas permeability | g·cm/ | ≤1.0x10-13 | |||||

Dimensional stability | ±2 | ||||||

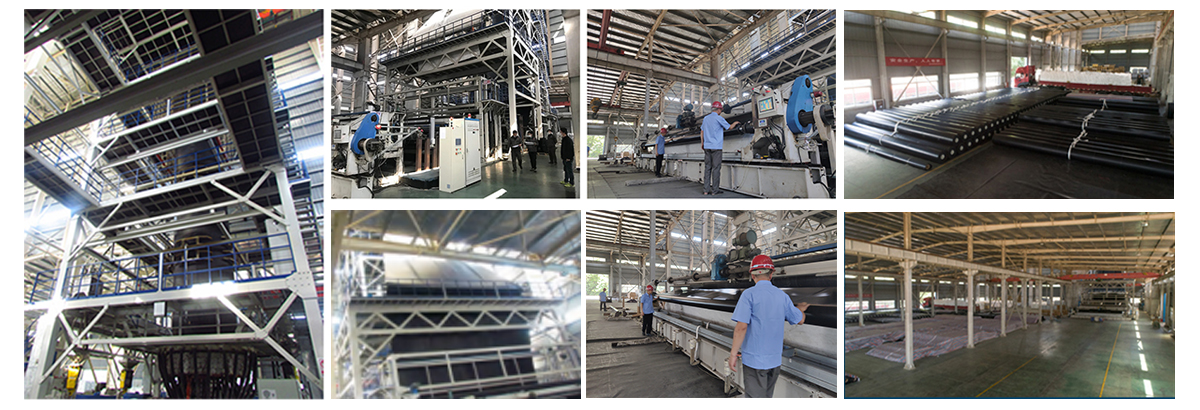

// COMPANY PRESENTATION //

// EQUIPMENT // // LABORATORY //

// LABORATORY // // HONOR //

// HONOR // // PROJECT ENGINEERING //

// PROJECT ENGINEERING //

Engineering case | Supply product | |

1 | Coal power project ash landfill project | 1.0mm HDPE Geomembranes |

2 | Potassium salt seepage control system engineering | 1.0mm HDPE Geomembranes |

3 | Smelter industrial waste water tank seepage prevention project | 2.0mm HDPE Geomembranes |

4 | Chemical gypsum slag field seepage prevention project | 1.5mm HDPE Geomembranes |

5 | Calcium free chromium residue wet detoxification and chromium recovery project | 2.0mm HDPE Geomembranes |

6 | Urban waste comprehensive treatment site upgrade project | 1.0mm HDPE Geomembranes |

7 | Solid waste disposal center safe landfill site | 1.5mm、2.0mm HDPE Geomembranes |

8 | Sewage diversion and biogas diversion project of domestic waste landfill | 2.0mm HDPE Geomembranes |

9 | Industrial solid waste disposal center project | 2.0mm HDPE Geomembranes |

10 | Livestock and poultry waste disposal and utilization project top membrane project | 1.0mm HDPE Geomembranes |

11 | Heavy metal waste resource harmless disposal project rigid landfill project | 2.0mm HDPE Geomembranes |

12 | Power plant dust ash landfill project | 1.0mm、1.5mm HDPE Geomembranes |

13 | Solid waste ash project in landfill reservoir area | 1.0mm、1.5mm HDPE Geomembranes |

14 | landfill storage pool covering project | 2.0mm HDPE Geomembranes |

15 | Emergency landfill project Geotechnical material laying project in the second landfill area | 1.5mm 2.5mm HDPE Geomembranes |

The project is constantly updated | ||

// MORE PRODUCTS //