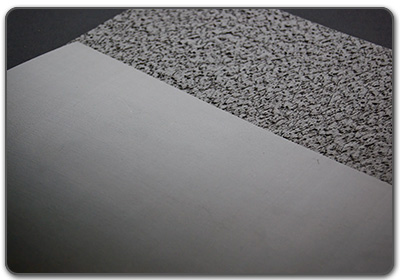

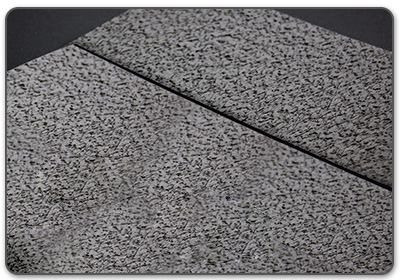

1, TP-GEO Single-sided Textured geomembrane is made of polyethylene resin (PE) as raw material, adding nanoscale carbon black and other additives.

2, With excellent anti-aging, anti-ultraviolet linearity, anti-oxidation, chemical corrosion resistance and resistance to biological enzyme degradation.

3. The rough geomembrane surface is in contact with steep slopes and soil, and has greater friction to ensure that the material does not slip during construction and use

4, Has a large elongation at break and tensile strength

// SORT //

|  |  |

| Smooth | Single-sided | Double-sided |

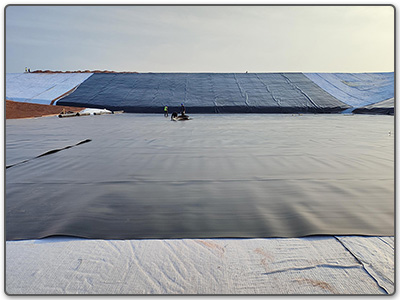

// APPLICATION SCENARIO //

|  |  |

Landfill | Anaerobic digestion ponds | Slag tailing ponds |

|  |  |

Wastewater lagoon | Swales | water reservoirs |

|  |  |

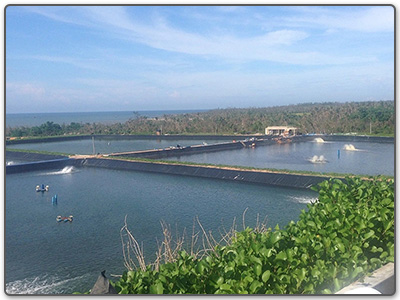

| Cultured fish pond | Mining heap leach | Slag tailing ponds |

// PRODUCT PARAMETER //

| HDPE Single-sided Textured (Execute GRI GM-13) | |||||||

Index | Unit | Test value | |||||

1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm | ||

Roughness height | mm | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

Minimum density | g/cm³ | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 |

Tensile property | |||||||

Yield strength(stress) | N/mm | 15 | 18 | 22 | 29 | 37 | 44 |

Breaking strength(stress) | N/mm | 10 | 13 | 16 | 21 | 26 | 32 |

Yield elongation | % | 12 | 12 | 12 | 12 | 12 | 12 |

Elongation at break | % | 100 | 100 | 100 | 100 | 100 | 100 |

Right Angle Tearing strength | N | 125 | 160 | 190 | 250 | 315 | 375 |

Puncture strength | N | 270 | 335 | 400 | 535 | 670 | 800 |

Resistance to environmental stress cracking | H | 300 | 300 | 300 | 300 | 300 | 300 |

Carbon black | |||||||

Carbon black content (range) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

Oxidation induction time(OIT) | |||||||

Standard OIT | min | 100 | 100 | 100 | 100 | 100 | 100 |

High pressure OIT | min | 400 | 400 | 400 | 400 | 400 | 400 |

85℃ Oven aging (minimum mean) | |||||||

After 90 days of baking, standard OIT | % | 55 | 55 | 55 | 55 | 55 | 55 |

After 90 days of baking, | % | 80 | 80 | 80 | 80 | 80 | 80 |

Uv resistance | |||||||

1600 hours of UV exposure, standard OIT | % | 50 | 50 | 50 | 50 | 50 | 50 |

1600 hours of UV exposure, | % | 50 | 50 | 50 | 50 | 50 | 50 |

Impact embrittlement performance at -70℃ | pass | ||||||

Gas permeability | g·cm/ | ≤1.0x10-13 | |||||

Dimensional stability | ±2 | ||||||

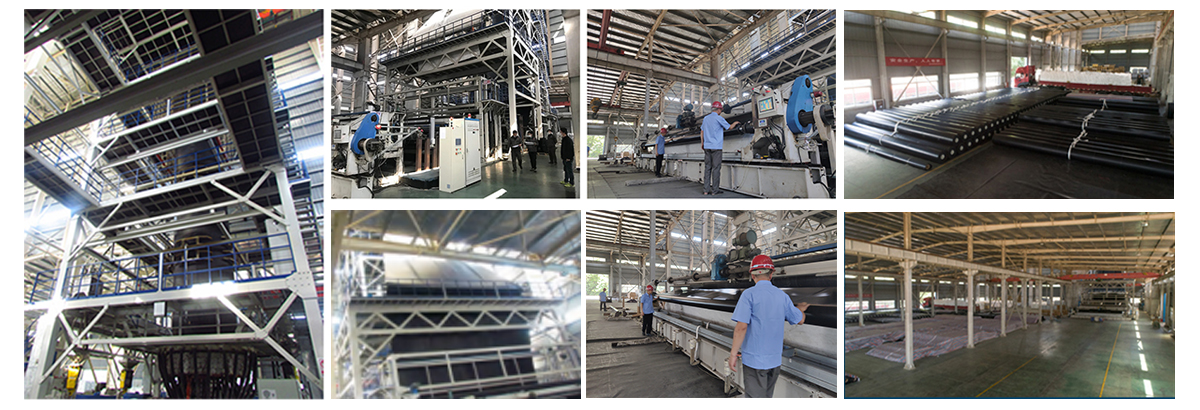

// COMPANY PRESENTATION // // EQUIPMENT //

// EQUIPMENT // // LABORATORY //

// LABORATORY // // HONOR //

// HONOR //

// PROJECT ENGINEERING //

Engineering case | Supply product | |

1 | Coal power project ash landfill project | 1.0mm HDPE Geomembranes |

2 | Potassium salt seepage control system engineering | 1.0mm HDPE Geomembranes |

3 | Smelter industrial waste water tank seepage prevention project | 2.0mm HDPE Geomembranes |

4 | Chemical gypsum slag field seepage prevention project | 1.5mm HDPE Geomembranes |

5 | Calcium free chromium residue wet detoxification and chromium recovery project | 2.0mm HDPE Geomembranes |

6 | Urban waste comprehensive treatment site upgrade project | 1.0mm HDPE Geomembranes |

7 | Solid waste disposal center safe landfill site | 1.5mm、2.0mm HDPE Geomembranes |

8 | Sewage diversion and biogas diversion project of domestic waste landfill | 2.0mm HDPE Geomembranes |

9 | Industrial solid waste disposal center project | 2.0mm HDPE Geomembranes |

10 | Livestock and poultry waste disposal and utilization project top membrane project | 1.0mm HDPE Geomembranes |

11 | Heavy metal waste resource harmless disposal project rigid landfill project | 2.0mm HDPE Geomembranes |

12 | Power plant dust ash landfill project | 1.0mm、1.5mm HDPE Geomembranes |

13 | Solid waste ash project in landfill reservoir area | 1.0mm、1.5mm HDPE Geomembranes |

14 | landfill storage pool covering project | 2.0mm HDPE Geomembranes |

15 | Emergency landfill project Geotechnical material laying project in the second landfill area | 1.5mm 2.5mm HDPE Geomembranes |

The project is constantly updated | ||

// MORE PRODUCTS //