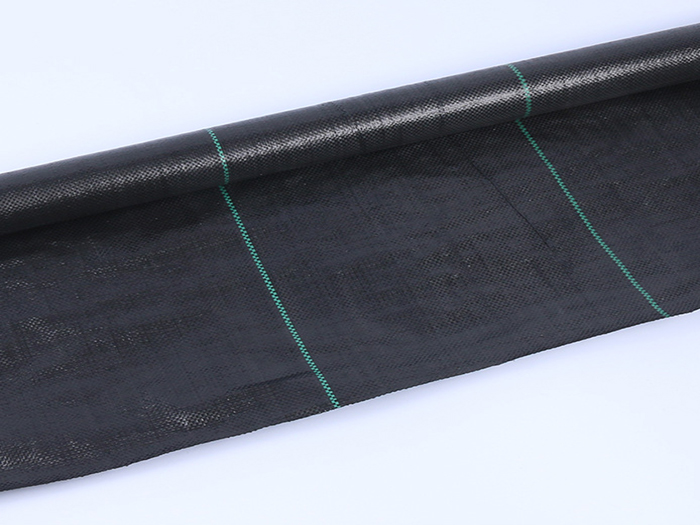

PP geotextile is a geosynthetic material made of polypropylene. PP geotextiles are used in civil engineering and construction projects. The main function of PP geotextiles is to improve the performance of soil, rocks, or other geotechnical engineering materials.

What Is PP Geotextile?

PP geotextile is a synthetic material usually made of polypropylene. Its primary role is to provide strength, filtration, separation, drainage, and erosion prevention in civil engineering projects. Specific applications include filtration, separation of different soil layers, soil reinforcement, drainage support, and soil erosion prevention.

What Is The Use Of PP Geotextile?

PP geotextile has a wide range of applications in construction and civil engineering. Its main uses include but are not limited to the following aspects:

1. Filtration and separation: PP geotextile is used to prevent fine soil particles from mixing with coarser materials, maintaining the separation of soil layers while allowing water to pass through.

2. Soil reinforcement: PP geotextiles are used in retaining walls, embankments, slope stabilization, and other applications to provide soil strength and stability to prevent collapse and erosion.

3. Drainage system support: Geotextiles are used in drainage systems to ensure that water can be drained while preventing soil particles from blocking drainage channels.

4. Prevent soil erosion: In environmental and landscape projects, PP geotextiles help control soil erosion and promote vegetation growth.

What Is The Production Process Of PP Geotextile?

Producing PP geotextiles usually includes the following steps:

1. Raw material selection: High-quality polypropylene resin is used as raw material.

2. Extrusion: Through the extrusion process, polypropylene is melted and extruded to form a thin and uniform cloth piece.

3. Shaping: The extruded fabric pieces are cooled and cut into the desired size and shape.

4. Processing: According to specific application requirements, geotextiles can be subjected to later processing, such as adding anti-UV materials, reinforcement layers, etc.

5. Quality control: Strict quality control procedures ensure that each batch of geotextiles meets relevant standards and specifications.

PP Geotextile Quality Control?

To ensure the quality of PP geotextile, our company implements strict quality control measures, including but not limited to the following aspects:

1. Raw material selection: We select high-quality polypropylene resin to ensure the stability and durability of the geotextile.

2. Production process monitoring: We conduct comprehensive production monitoring to ensure the stability and consistency of the extrusion and molding process.

3. Product testing: Each batch of geotextiles will undergo rigorous physical and chemical testing, including tensile strength, permeability, aging resistance, etc.

4. Follow standards: Our geotextiles follow relevant international and domestic standards to ensure that product quality and performance meet requirements.

As a professional PP geotextile manufacturer, we take high quality, reliability, and customer satisfaction as our core values. We have advanced PP geotextile production equipment and an experienced technical team, able to provide a variety of specifications and customized PP geotextile products to meet the needs of different projects. We are committed to providing customers with the highest quality products and providing professional technical support and solutions. No matter what type of PP geotextile your project requires, we can meet your requirements and offer competitive prices. If you have related projects, you can contact us, and we will provide you with professional guidance and free samples online 24 hours a day!